NEWS

- HOME

- NEWS

Principle of Rubber Microwave Vulcanization Machine

Rubber vulcanization can be achieved through various methods. The traditional method is to use vulcanization processes such as steam or far-infrared heating to cure the rubber material. However, due to the slow thermal conduction from the outside to the inside of the medium during heating, rubber material is a poor thermal conductive material. For rubber, heating relies on the surface of the material to the inner layer, and the heat transfer rate is very slow. Most of the time is spent on making the rubber reach the vulcanization temperature. So the heating time is long, the efficiency is low, and the uniformity of vulcanization is poor. Especially in the old process, magnesium silicate (talc powder) was used to eliminate rubber adhesion, which caused dust to diffuse in the rubber production workshop and the dust content in the air far exceeded the standards set by the national environmental protection department. Moreover, the overall vulcanization state of rubber is not ideal, because under conventional heat conduction conditions, the surface temperature of the vulcanized rubber material does not rise at the same time as the inner layer, resulting in uneven vulcanization.

Microwave heating is completely different from traditional heating methods, as it penetrates microwave energy into the heated medium and directly heats it as a whole. Therefore, heating is rapid, efficient, and energy-saving, greatly shortening the rubber vulcanization time, improving heating uniformity, and achieving higher vulcanization quality. It can quickly bypass the induction stage where rubber is prone to adhesion and enter the pre sulfurization stage, eliminating the use of talc powder in the old process and meeting environmental requirements. This production process can concentrate most production processes on one production line, with high automation, low energy consumption, labor savings, stable production, and uniform product quality, greatly improving production labor conditions.

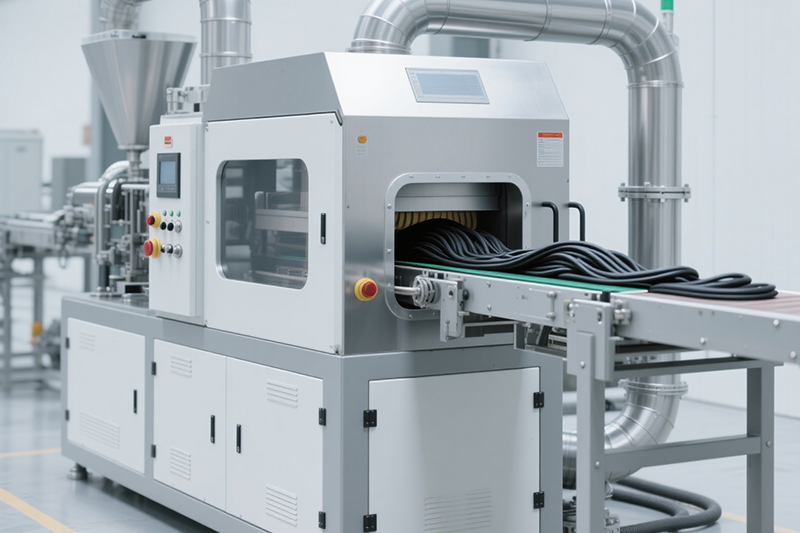

The most practical basic process for microwave rubber vulcanization is as follows: the molded product extruded from the extruder is transported by a conveyor belt or roller conveyor, enters the microwave vulcanization device, where the rubber is rapidly heated to the vulcanization temperature, and then enters the hot air tank for secondary vulcanization. The rubber is held at a certain temperature in the hot air tank for a certain period of time to complete the foaming and vulcanization process of the product. If the hot air tank is not used at this time and vulcanization is carried out entirely in the microwave tank, it would be too wasteful of energy, and combining it with the hot air tank would be more economical.

The composition of the microwave rubber vulcanization production line includes extruders, high-temperature shaping equipment, microwave vulcanization equipment, hot air vulcanization equipment, cooling sections, tractors, cutting machines, punching machines, etc.

Extrusion Machine:Used to extrude rubber raw materials into the desired shape and structure, extruded rubber is divided into single-layer rubber (sponge or solid core rubber), two-layer composite rubber (sponge and solid core rubber), three-layer composite rubber (steel core, sponge and solid core rubber), four layer composite rubber, etc. The structure and performance of the extruder used for different types and specifications of rubber also vary.

High Temperature Shaping Equipment:Mainly used to rapidly vulcanize and shape the surface of freshly extruded rubber at high temperatures, preventing deformation or adhesion to conveyor belts that may damage its surface.

Microwave Vulcanization Equipment:Using microwave heating speed to heat the whole to the temperature required for vulcanization, this process only takes a few tens of seconds to one or two minutes.

Hot Air Vulcanization Equipment:Keep the rubber strip within the temperature range required for vulcanization and continue vulcanization.

Cooling:Used to cool the rubber strip to a temperature suitable for cutting, collecting, and other operations.

Traction Machine:Provide power for the rubber strip to move forward.

The above is just the basic configuration of vulcanized rubber strips. When vulcanizing rubber strips with skeleton, there is also a steel core supply equipment in the front section of the extruder, and sometimes punching machines, steel core forming machines and other equipment are also equipped in the rear section as needed; When sulfurizing non strip continuous products, no cutting machine is required.

Microwave heating equipment is the core component of the entire microwave vulcanization process. The uniform heating design of microwave heating equipment is particularly important. The uniform heating design of microwave heaters is a prerequisite for the uniform vulcanization of rubber. In addition, the composition ratio, color depth, and surface smoothness of the rubber material will affect the microwave digestion and absorption performance of microwave rubber vulcanization, and appropriate coordination needs to be considered in the microwave heating process to meet the requirements of the process.

Principle Of Microwave Heating﹕

Microwaves are electromagnetic waves with frequencies ranging from 300 megahertz to 300 gigahertz and wavelengths of 1 meter to 1 millimeter. Microwaves are commonly used for information transmission in radar and communication technology. In the field of modern science and technology, it has been expanded and applied as a new energy source. China started research and application in the 1970s, exploring and testing its application in various fields. At present, the microwave frequencies used for industrial heating are 915 MHz and 2450 MHz, which have achieved many application results.

Usually, materials are composed of polar and non-polar molecules. Under the action of microwave electromagnetic fields, polar molecules can be shifted from their original thermal motion state, and the orientation of polar molecules can be changed according to the direction of the electromagnetic field. Molecules generate frictional heat during motion, and the energy conversion of alternating electromagnetic fields in this microscopic process is called thermal energy inside the medium, causing a macroscopic increase in the temperature of the medium. This is a simple explanation of the principle of microwave heating.

Microwave heating utilizes the principle of high-frequency oscillation, where electromagnetic waves of high-frequency energy radiate towards the heated material, heating both inside and outside the material simultaneously. After being exposed to radiation, a substance is heated due to its own medium loss, without the need for thermal conduction or convection. Therefore, substances can be quickly heated, and both the inside and outside of the substance are heated simultaneously, resulting in uniform heating temperature and improved product quality.

Rubber materials contain carbon black, sulfur, and additives inside, as well as a large amount of polar water molecules. Under the action of microwave electromagnetic field energy, intense oscillations and thermal energy are generated, causing the rubber material to heat up to the vulcanization temperature and achieve rubber vulcanization. From this, it can be seen that microwave heating is the effect of electromagnetic field energy on the medium. The medium itself loses heat under the action of electromagnetic field energy, and the temperature of the substance increases due to the effect of energy. Metal materials cannot be heated by microwaves because electromagnetic fields cannot penetrate the interior of the material. When subjected to electromagnetic fields on the surface of the material, the surface of the metal material reflects the energy of the electromagnetic field, and the metal material cannot absorb microwaves. The characteristics of water make it the best absorbing medium for microwaves. Therefore, any material containing water can absorb microwaves and be heated up by them.

In the continuous vulcanization process of rubber products, the thermal conductivity of rubber is extremely poor. It takes a long time to heat the entire cross-section of the product to the required vulcanization temperature using conventional heating vulcanization methods, and uneven heating of the material can cause over sulfuration on the surface of the rubber product, resulting in internal under sulfurization defects in the center of the rubber product. The heating of microwave energy can quickly heat the entire cross-section of rubber products to the required vulcanization temperature, and then enter the insulation channel of conventional heating. Its main function is to prevent the temperature of rubber products from dropping during vulcanization reaction, so it is necessary to quickly heat rubber products to reach the vulcanization temperature range. Then further heat the surface of the rubber product in the insulation channel to the temperature required for surface vulcanization. Try to maintain temperature stability and thermal balance, while also paying attention to thermal energy loss, temperature fluctuations, and temperature control. Otherwise, it will affect the vulcanization quality of rubber products, and strict attention must be paid to the operation.

The dielectric constant of natural rubber is 2.15、

The dielectric constant of chloroprene rubber is 4.0、

Natural rubber medium loss angle tgδ=0.003、

Chloroprene rubber dielectric loss angle tgδ=0.034、

The above shows that the physical and chemical properties of rubber are different in microwave electromagnetic fields. Natural rubber media has a smaller loss angle and is not easily heated by microwaves. To achieve the same effect, it is necessary to increase the energy of the microwave electromagnetic field and increase the electric field strength. Due to the different dielectric constants of different materials, there are differences. Different types of rubber must use corresponding heating equipment and make corresponding adjustments during microwave vulcanization to ensure the vulcanization effect of rubber products, which must be taken into account.

The technical parameters of the microwave rubber vulcanization equipment are as follows::

一、Technical parameters of microwave rubber vulcanization section (one unit)

1、Microwave Frequency:2450MHZ

2、Microwave Power:10KW(Adjustable)

3、Automatic Temperature Control:Can achieve automatic temperature control within 240 ℃

4、Belt width:230mm

5、Transmission Speed:1.5~14m/min

6、The drive belt is equipped with a pneumatic photoelectric correction mechanism and a drive belt tensioning mechanism.

7、The drive belt inlet is equipped with a high infrared preheating lamp tube(1KW)。

8、Size: (Length X Width X Height)28000×600×1500mm

二、 Technical parameters of hot air vulcanization section (two units)

1、Hot Air Power:28KW(Internal Circulation)

2、Automatic temperature control: can achieve automatic temperature control within 240 ℃

3、Belt width:230mm

4、Transmission Speed:1.5~14m/min

三、Cooling water tank (one unit)

1、The flow rate of water can be adjusted

2、Slot Length 4000mm, Slot Width 570mm

四、Equipment Features:

1、The speed of continuous vulcanization production is fast and the efficiency is high, which is six times that of traditional equipment.

2、Permeation heating, temperature controllable, uniform vulcanization, bright color.

3、Total length of equipment:28m

Used for rapid and uniform vulcanization of rubber strips, tapes, hoses, rubber seals, and foam rubber strips. The surface gloss of the rubber strip vulcanized by this equipment is good, delicate, and highly elastic. The processing environment is green and environmentally friendly, with no pollution.